Join Over 1000+ Companies with Mask Polymer Here

- Founded in 1997, Mask Group has built over two decades of specialized expertise in designing and manufacturing advanced rubber components for both automotive and non-automotive applications. Operating from our headquarters in Pune, India, we are strategically located near major OEMs and Tier-1 suppliers, enabling rapid collaboration, efficient logistics, and dependable support.

- Our capabilities span a comprehensive portfolio of precision rubber-moulded components, extruded rubber profiles, and rubber-to-metal bonded parts, engineered to meet the demanding performance and durability standards of modern mobility. Every component we produce reflects our unwavering philosophy — Built to Last, Driven to Perform — ensuring long-term reliability and high performance under real-world conditions.

- We proudly supply high-quality rubber solutions to the passenger vehicle, commercial vehicle, two-wheeler, and emerging EV segments, serving as a trusted partner to more than 50 OEM and Tier-1 customers worldwide. With a steadfast commitment to quality, innovation, and customer-centric engineering, we continue to advance and shape the future of automotive rubber technology.

Group Companies and Strategic Joint Ventures:

01.

Mask Polymers

Leading supplier of Rubber moulded parts, Rubber-to-metal bonded components, and Extruded profiles and hoses for the automotive sector/non-automotive sector

02.

Insit-Mask

A strategic global joint venture between Mask Polymers(India) and INSIT Group, Italy, specializing in Constant Velocity Joint (CVJ) boots, Steering column bellows in TPE and TPV material, as well as Rubber gaskets for Engine applications

03.

Manas Automotive

A joint venture between Mask Polymers and Belrise Industries, focused on the manufacturing of automotive rear-view mirrors and other plastic components for applications such as: Commercial Vehicle, Passesger Vehicles, 2 wheeler and 3 wheelers.

04.

Mask Staples

Mask Staples is our diversification in the food industry aiming to deliver pulses, grains, spices, and plant-based proteins through advanced processing, packaging, traceable sourcing, and a zero-waste model.

Mask Polymer Pvt. Ltd. - Manufacturer of rubber moulded, rubber to metal bonded & rubber to teflon bonded in Pune, Maharashtra.

"Our vision is to become the most preferred supplier- locally and globally- for all our product categories by delivering excellent customer service, competitive pricing and exceptional quality. We are committed to implementing and promoting environmentally sustainable practices within our company and throughout our entire supply chain"

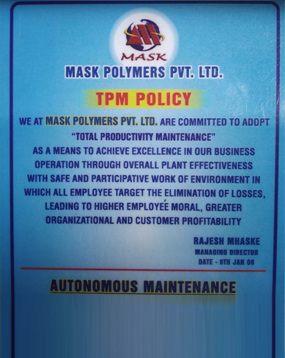

"At Mask Group, we are committed to excellence and continual improvement in everything we do. Through the adoption of cutting-edge technologies and robust quality processes, we strive to deliver superior automotive rubber solutions that consistently achieve and exceed customer satisfaction."

Why Choose MASK!

Seamless Process, Great Results.

Developing personalized customer journeys to increase satisfaction and loyalty.

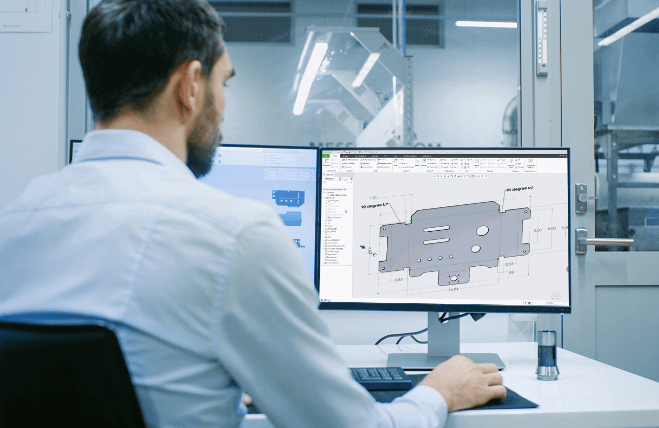

Discovery & Planning

The first step in our process is understanding your unique business needs, objectives, and our cutomes challenges.

Execution & Delivery

Once the plan is in place, our team moves forward with execution, turning strategies into actiony to deliver.

Review & Support

After project completion, we conduct a thorough review to ensure everything aligns with your goals and requirements.

Empowering Business with Expertise.

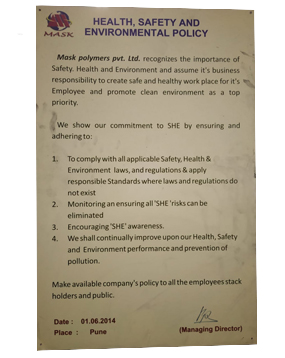

Sustainability

We prioritize environmentally responsible operations, resource optimization, and long-term practices that contribute to a cleaner, greener future.

Customer Success

Our customers’ growth is our success. We work closely with partners to understand their needs and deliver solutions that ensure performance, reliability, and satisfaction.

Innovation

We continuously explore new materials, technologies, and engineering methods to deliver advanced, future-ready automotive rubber components.

Integrity

Honesty, transparency, and ethical conduct form the foundation of every decision, relationship, and commitment we uphold.

People Development

We are committed to the continuous development of our employees through structured training, skill enhancement, and a culture that encourages learning and career growth.

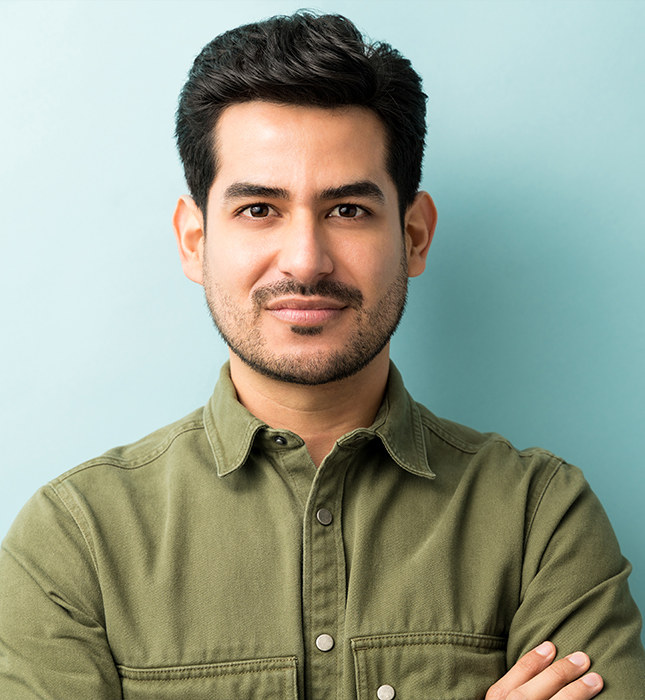

About the Founder!

Founder & Managing Director, Mask Group

Mechanical Engineer | Industry Leader

"Innovation is not an option; it is the engine that drives our next milestone."

Mr. Rajesh Mhaske established Mask Group in 1997 with a vision to deliver precision-engineered rubber components to the automotive industry. A mechanical engineer by profession, he combines deep technical expertise with strong strategic leadership, growing the company from a small unit started in his home into a trusted supplier serving 50+ OEM and Tier-1 customers across the globe.

Beyond Mask Group, Mr. Mhaske holds a respected position in the industry and actively contributes to education and entrepreneurship development.

- Chairman, Western Region – All India Rubber Industries Association (AIRIA)

- Chairman, Nutan College of Engineering and Technology

- Founder & Director, Nutan Incubation Center for Entrepreneurship Development

- Director at Paiva Fund Glassworks

Mr. Rajesh Mhaske envisions Mask Group becoming a ₹500-crore company by 2030, driven by continuous innovation, adoption of advanced technologies, and a strong competitive edge in the automotive rubber industry. A core part of his vision is the growth and development of every employee, achieved through structured training, skill enhancement, and a culture that empowers people to excel and progress along with the company.

Our Legacy – Tribute to our Guide & Mentor

Late Shri Krishnarao Bhedge

He believed that strong institutions are built not only on expertise, but on character — on discipline, honesty, resilience, and a sense of responsibility toward others. These principles continue to shape our company’s culture, decisions, and long-term vision.

Today, every product we create and every milestone we achieve carries a reflection of his teachings. This tribute honours the extraordinary human being who shaped our journey — not only as a mentor and guiding force, but as family.

We are proud to dedicate this chapter of our growth to Shri Krishnarao Bhegade — the foundation of our values, the inspiration behind our progress, and the timeless compass that guides our future.

Commercial Vehicle Applications / 2 Wheeler Applications

ORVM & IRVM

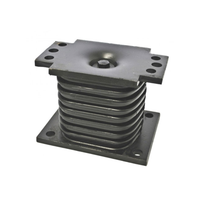

Shock Absorber

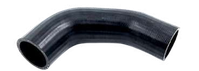

Exhaust Duct

Radiator & Coolant Hoses

Torque Rod

Bushings

Mountings

Suspension Parts

Wheel Damper

Foot Rest Rubber

Handle Grip

Chain Guide

Rear View Mirror

Carburetor Sleeve

Fuel Tube

Cable Guide

Products and Applications!

Door Insulation

Our PE and XLPE foam door insulation solutions are specially engineered to improve the NVH (Noise, Vibration & Harshness) performance of passenger vehicles. Manufactured using advanced extrusion and thermoforming processes, these foam profiles combine lightweight design with superior acoustic and thermal insulation properties. Strengths: Exceptional NVH reduction, providing a quieter and more refined cabin experience Uniform density and structure, enabling consistent sound damping and moisture barrier performance Custom-designed profiles that perfectly fit into passenger car door assemblies Excellent resistance to compression set, heat, and environmental aging Enhanced sealing and airflow management, improving overall door system efficiency

Sun-Roof Draintubes

Our Sunroof drain tubes are engineered to deliver reliable, long-lasting water management performance in modern passenger vehicles. Manufactured using advanced precision extrusion and thermoforming technology, these tubes ensure smooth drainage and effective protection against leaks, moisture buildup, and interior damage. Strengths: Premium TPE construction offering outstanding flexibility, durability, and resistance to environmental exposure Precision-formed geometry for perfect integration with complex roof structures Superior water-flow characteristics ensuring quick and obstruction-free drainage Excellent resistance to temperature variations, UV exposure, and vehicle vibration

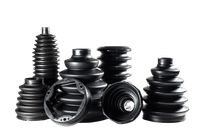

CVJ Boots and Bellows-in TPE and Rubber

We manufacture high-performance boots in both Rubber and TPE, engineered to deliver exceptional protection, durability, and flexibility for a wide range of automotive applications. Our boots are designed to perform reliably under constant motion, exposure to environmental contaminants, and demanding operating conditions. Key Strengths

- Available in TPE and Rubber, based on OEM requirements

- Excellent flexibility and articulation for continuous movement

- High resistance to dust, water, chemicals, and road debris

- Superior tear, abrasion, and fatigue performance

- Precision-engineered for secure sealing and long service life

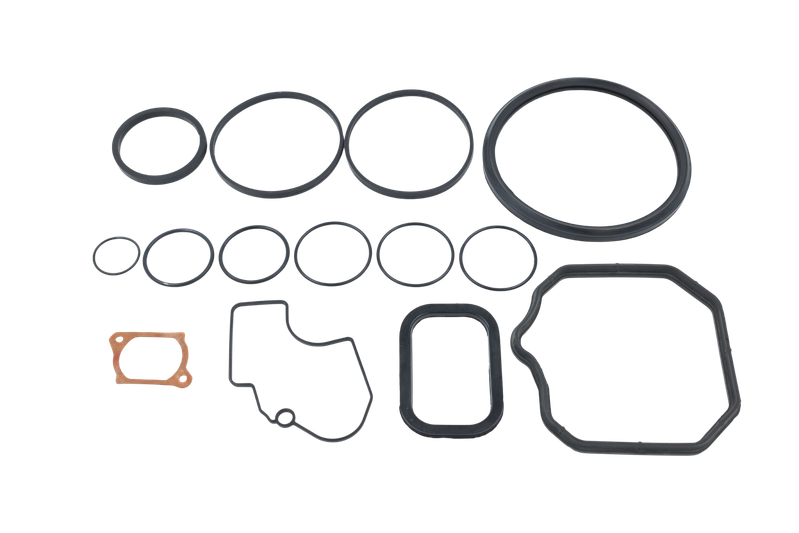

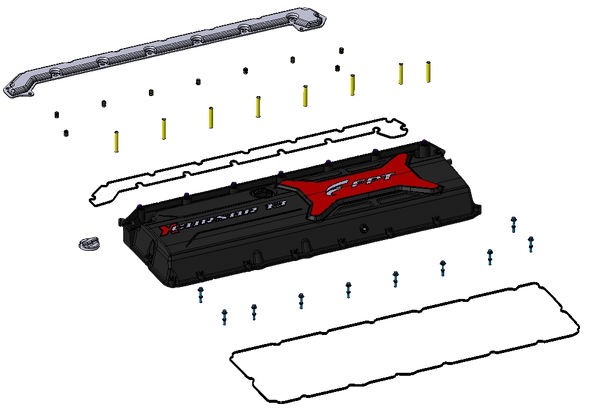

Rubber Gaskets, Rubber O-rings

Our gasket and O-ring solutions are engineered for high sealing performance, durability, and precision fit across demanding automotive applications. We manufacture a wide range of rubber gaskets, cylinder head cover gaskets, and custom sealing components, designed to ensure leak-proof performance under extreme temperatures, pressures, and operating conditions.

With the support of our technical partner INSIT Italy, we offer end-to-end expertise in developing high-precision gaskets for all engine platforms, delivering custom sealing solutions that meet stringent global OEM standards and customer requirements.

Using advanced compounding and molding techniques, we deliver components that offer:

- Superior sealing efficiency for fluids, oils, coolants, and gases

- High resistance to heat, pressure, and chemical exposure

- Consistent dimensional accuracy for reliable assembly and long service life

- Custom formulations including NBR, EPDM, silicone, FKM, and other elastomers

- Application-specific designs to meet OEM and Tier-1 engineering requirements

We’ve offred the best pricing for you

Hear from Our Customer.

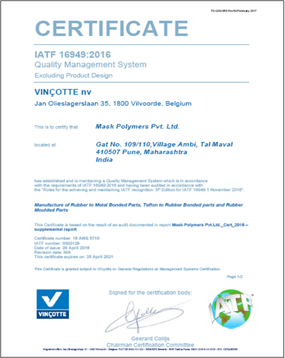

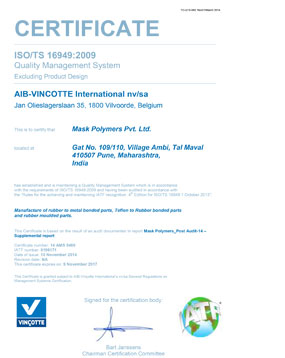

Certificate

People Behind Mask Polymer.

Strategies and Insights.

Developing personalized customer journeys to increase satisfaction and loyalty.